- About Us

About

Forging Future Excellence with Innovation and Collective Expertise

Group Companies

Strength in Unity

- Our Services

- Software Product Engineering

- Hire Dedicated Development IT Teams In India

- QA & Testing

- Custom Application Development Services

- E-Commerce

- Data Engineering

- Artificial Intelligence

- Cloud Services

Software Product Engineering

Developing Innovative Software Products

Dedicated Software Teams

Committed Skilled Software Developers

QA & Testing

Precision in Quality Assurance

Application Development

Crafting Custom Applications

E-Commerce

Empowering Online Retail Experiences

Data Engineering

Mastering Data Solutions

Artificial Intelligence

Powering with AI Innovations

Cloud Services

Premium Cloud Services Offered

- Solutions

- Financial Management Services

- Workforce Management

- Human Resource Management

- E-Learning

- Supply Chain Management

- Fleet Management

- CRM

- Operations Management

- Asset Management

- Web Portals

- Content Management System

- ERP

- Document Management

- RPA

Financial Management Services

Enhancing Financial Operations Suite

Workforce Management

Optimizing Workforce Efficiency Solutions

Human Resource Management

Streamlining HR Operations Solutions

E-Learning

Revolutionizing Online Learning Experiences

Supply Chain Management

Efficient Solutions for Supply Chains

Fleet Management

Optimizing Fleet Operations Solutions

CRM

Empowering CRM Solutions

Operations Management

Enhancing Operational Efficiency Solutions

Asset Management

Maximizing Asset Value Solutions

Web Portals

Creating Seamless Web Experiences

Content Management System

Efficient Content Management Solutions

ERP

Integrated Business Solutions Platform

Document Management

Effortless Document Management Solutions

RPA

Automating Business Processes Solutions

- Technologies

Mobility

Wireless Connectivity Empowering Accessibility

Web Technologies

Enhancing Online Presence

ERP Technologies

Integrating Business Operations

ETL Technologies

Streamlining Digital Data Integration

Cloud Technologies

Infrastructure with Cloud Innovations

Data Technologies

Maximizing Business Insights

- Industries

- Healthcare

- Fintech

- BFSI

- Telecommunication

- Automotive Industry

- Retail and eCommerce

- Logistics & Transportation

- Travel & Tourism

- Media and Entertainment

- Oil & Gas

- Professional Services

Healthcare

Empowering Wellness Through Innovation

Fintech

Revolutionizing Finance, Digitally Empowered

BFSI

Navigating Finances with Expertise

Telecommunication

Connecting Beyond Boundaries

Automotive Industry

Driving Innovation Forward

Retail and eCommerce

Elevating Retail Experiences

Logistics & Transportation

Efficiency in Motion

Travel & Tourism

Adventures Await, Seamlessly

Media and Entertainment

Entertainment Redefined, Always

Manufacturing

Crafting Future Solutions

Oil & Gas

Fueling Future Possibilities

Professional Services

Excellence in Every Service

Education and eLearning

Learning without Limits

ISV

Empowering Software Innovations

- Case Studies

- Contact Us

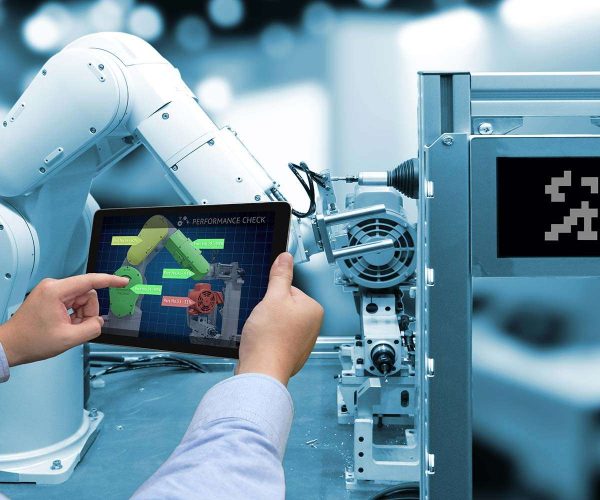

Revolutionizing Manufacturing with Innovative Software Solutions

The manufacturing industry is experiencing a profound transformation driven by innovative software solutions. Strawberry Infotech, a leading software development company, is at the forefront of this evolution, empowering manufacturing businesses to enhance productivity, reduce costs, and drive greater efficiency. Join us on a journey to explore how software development is reshaping the manufacturing sector, and discover how Strawberry Infotech is leading this digital revolution.

OUR CLIENTS

Smart Factory and Industrial IoT

Skillset: IoT Device Integration, Sensor Networks, Data Analytics

Smart factories are the future of manufacturing. Our expertise includes:

Connecting manufacturing equipment and machinery to the internet for real-time data collection.

Implementing sensor networks to monitor equipment performance, temperature, and environmental conditions.

Analyzing data from IoT devices to optimize processes, reduce downtime, and improve quality.

Digital Twin and Simulation

Skillset: Digital Twin Development, 3D Modeling, Simulation Software

Digital twin technology is revolutionizing product design and manufacturing. Our capabilities encompass:

Building detailed 3D models of products for design and testing.

Developing simulations to test and optimize manufacturing processes before implementation

Supply Chain Management and Optimization

Skillset: Supply Chain Software, Inventory Management, Demand Forecasting

Effective supply chain management is critical for manufacturing success. Our skills include:

Designing software solutions for end-to-end supply chain visibility and control.

Developing systems for real-time inventory tracking and optimization.

Implementing forecasting algorithms to anticipate market demand and adjust production accordingly.

Production Monitoring and Quality Control

Skillset: Production Monitoring Systems, Quality Control Software, Predictive Maintenance

Real-time production monitoring and quality control are essential. Our proficiencies encompass:

Building solutions for real-time tracking of production progress and equipment performance.

Developing quality control systems to ensure product consistency and compliance.

Using data analysis to predict equipment maintenance needs and reduce downtime.

Manufacturing Execution Systems (MES)

Skillset: MES Software, Shop Floor Automation, Work-in-Progress Tracking

Manufacturing execution systems streamline production processes. Our capabilities cover:

Designing software for real-time production tracking, scheduling, and reporting.

Implementing automation solutions for manufacturing processes.

Monitoring the movement of materials and products throughout the production cycle.

Process Optimization and Lean Manufacturing

Skillset: Process Modeling, Lean Six Sigma, Continuous Improvement

Process optimization is central to Lean manufacturing principles. Our expertise includes:

Creating digital models of manufacturing processes for optimization.

Applying Lean methodologies and Six Sigma practices to reduce waste and enhance efficiency.

Supporting ongoing process enhancement for increased productivity.

Human-Machine Interface (HMI) and Control Systems

Skillset: HMI Software, PLC Programming, Control System Integration

User-friendly HMI and control systems are crucial for manufacturing. Our skills encompass:

Designing intuitive interfaces for operators and production control.

Programming and integrating programmable logic controllers for machinery control.

Integrating control systems to ensure seamless operation.

Strawberry Infotech is committed to revolutionizing the manufacturing industry through innovative software solutions. We are dedicated to helping manufacturers harness the power of digital transformation, enabling them to adapt to changing market dynamics, increase productivity, and maintain a competitive edge in a rapidly evolving landscape.

If you’re ready to embark on a journey of digital transformation in the manufacturing sector, get in touch with us today. Strawberry Infotech is your trusted partner in delivering software solutions that optimize manufacturing processes, reduce costs, and elevate productivity in the industry.

Book Free Consultation

Get Custom Solutions & Recommendations, Estimates.

Fill up your details

Get Custom Solutions, Recommendations, Estimates.

What's next?

One of our Account Managers will contact you shortly